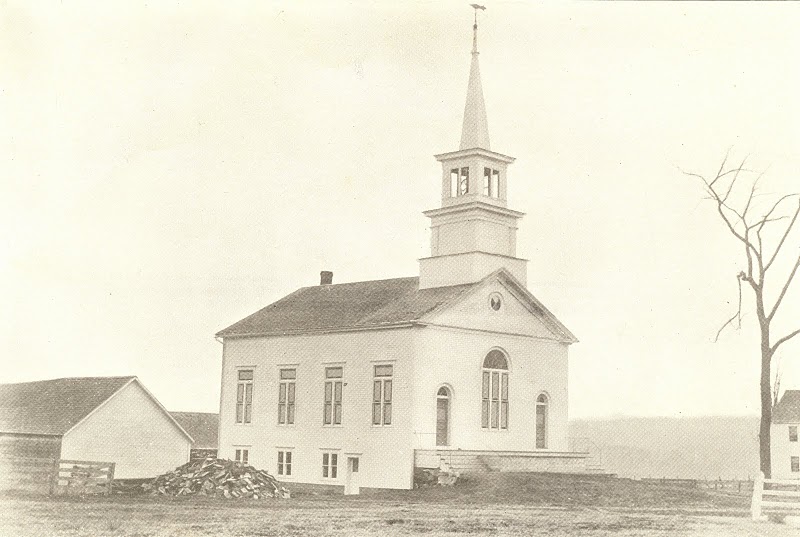

South Woodstock, VT

Project Overview

The South Woodstock Community Church was constructed in 1839. A meetinghouse, constructed in 1792, had been dismantled in the 1830’s and many of its timbers were incorporated into the Community church. The steeple of the church was severely damaged by water and in danger of complete failure. We had the opportunity to work as sub-contractors for Jan Lewandoski in the restoration of this steeple and first interior truss.

To date, we have never seen so much damage on a structure still standing. Both of the telescoping towers had sustained heavy damage. When we first saw the interior of the steeple base, we were horrified at what we observed. Giant formations of mold and fungus were all over the timbers. Ice had formed where water had been cascading down the inside of the hollow posts and out through the checks and mortises. Poorly executed repairs of ganged dimensional lumber were interspersed with the failing timbers. Although the caretakers of the church were not quite ready to execute a full restoration of the steeple, it was clear that the steeple would have to be removed or risk a collapse. The decision was made to remove the steeple and upper tower. The low-pitched slate roof above the octagon was the only part of the steeple not requiring serious repair. The roof and bell were flown off and placed on cribbing on the ground. The bell deck was then flown out followed by the upper tower. One bent of the upper tower was able to be removed intact. The remaining two posts of the upper tower were disintegrated to the point where they had to be removed in small pieces. Although the lower tower had also suffered extensive damage to some of the posts and portions of the plates, we did not remove any of its timbers at that time. A temporary roof was flown into place to protect the church where the steeple had been.

Almost a year after removing the steeple, we began cutting new parts for the towers and bell deck off site. Three of the damaged posts were replaced entirely and repairs were made to the remaining original posts. One of the plates in the lower tower had to be re-fabricated and repairs were made to another section of plate. The plates of the upper tower had to be re-made entirely along with several of the rafters in the bell deck. The bell deck featured a short, eight-sided king post with mortises of each of the rafters. Perhaps the most unique and interesting feature of this steeple are the eight butternut columns seen at the level of the bell deck supporting the roof and weathervane. These columns are believed to have been from the earlier meetinghouse and show evidence of supporting a tall spire at one time. These columns are turned where visible but were left rough where they rest on their sleepers below the bell deck. Two of these columns had to be replaced entirely and repairs were made to the remaining original columns. This was a rare opportunity for Seth Kelley and Michael Cotroneo. The new columns were made of butternut donated by a generous local landowner. Seth and Michael shaped the new columns by hand with drawknives and curved wooden planes.

When all of the new parts were made, we transported them to the church yard and began to rebuild the upper tower on sleepers placed on cribbing. The bell deck was assembled with custom metal roofing in place. The roofing had holes with tall metal cylinders to accommodate and protect the columns. The bell deck was lifted and placed on top of the tower posts with the eight butternut columns inside of the tower resting vertically but at ground level. With the bell deck in place, the columns were lifted in pairs through the holes in the roof and the sleepers slipped underneath of them. The tops of the columns were spaced appropriately and held in place for the voyage back to the top of the church using strapping. The tower was mostly trimmed and sheathed on the ground with openings for the rigging. Before the upper tower was replaced, the first interior truss was reinforced with the addition of a straining beam and additional struts going from the queen posts to the lower chord. This was done to better distribute the load of the steeple and correct the noticeable backward lean of the steeple over the church. The tower was flown back into place, the bell was slipped back between the columns and finally the roof was set in place. The roof of the lower tower was rebuilt and covered with new metal and the steeple was buttoned back up. This steeple was restored not a moment too soon and it scares us to wonder how close it came to failure and how many other structures might currently be in similar peril.

United Church, Craftsbury Common, VT

Project Overview

We had the privilege of sub-contracting this project for Jan Lewandoski during the summer of 2006. The church was constructed in 1816. The steeple of the church had suffered from years of water damage. The base of the spire had been completely destroyed by rot. The 8×8 timbers that make up the base of the spire had been sistered with additional 8×8 timbers that had also rotten completely. The roofing material covering the spire base had failed and allowed water to infiltrate. Previous efforts to shore up the steeple, a few decades earlier, ultimately exacerbated the problem and accelerated the deterioration by using a rubber membrane underneath of the roofing material and around the base of the spire. The rubber membrane actually trapped water in with devastating consequences.

We removed the spire from the church and completely dismantled it. None of the timbers in the base were salvageable. The feet of the spire rafters were also damaged but we were able to repair them all. The top of the spire mast that protrudes above the rafters had been removed decades earlier and been replaced with an aluminum replica visibly attached to the exterior of the spire with long metal plates and bolts. Using old photographs of the church we were able to determine that the details of the astragal molding on the spire and slight entasis of the mast had been lost in the previous efforts to restore the steeple. Our good friend Michael Cotroneo scarfed on a new mast top and custom milled all of the molding to match the old photographs.

After making the new spire base and repairing all of the rafter feet we rebuilt the spire on the ground. The spire was painted, and the custom metal roof was installed. The weathervane was reconfigured for the original mast style and installed. Before placing the spire back atop the steeple, the post tops and braces needed to be repaired. Most of the tenons that engaged the spire base were rotted and required repair. The intersection of two of the plate timbers and a post top in the lower tower also required a fair amount of repair. After scarfing in new timber to the plates and free-tenoning the post top we finally lifted the spire back into place and buttoned up the steeple.

One of the really interesting aspects of this project was the discovery that the first incarnation of the steeple had quite a different configuration. Mortises inside of the towers indicated an octagonal arrangement of posts protruding through the bell deck. Additional evidence of a different arrangement of the steeple was found between the lower telescoping tower and the plinth. Clapboards and trim can be seen here with evidence of having spent many years exposed to the elements in addition to what appeared to be burn marks. Perhaps the original steeple had been destroyed by lightening? Historic documentation and photographs from the centennial celebration of the church gave no indication of any other configuration of the steeple. We love a good mystery!

South Strafford Universalist Church

Project Overview

I worked with Jan Lewandoski as a sub-contractor on the South Strafford Universalist Church. This church dates from 1833. The project required over thirty feet of the sill on the front gable of the church to be replaced. Years of water splashing back from the concrete entry caused significant rot. I counted the growth rings on the old sill timber and lost count somewhere around one hundred and sixty years meaning that the tree for the front sill must have been a seedling sometime in the later 1600’s. After completing the sill work, we moved on to the steeple. We replaced several tower girts in kind. The trusses in this building were spaced thirty-nine inches apart, a very strong roof. I’ve been in many church roofs and this is the only one that I’ve seen like this. I must say that the roof line looks great.

-Seth Kelley

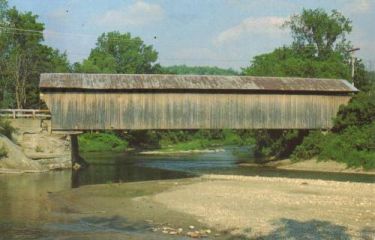

Willard Twin bridge, Hartland, VT

Project Overview

Seth Kelley worked on this covered bridge as a sub-contractor for Jan Lewandoski in 2001. A hurricane had destroyed the original bridge during the 1930’s. The state had replaced the bridge with one built of concrete. The concrete bridge began to crumble and fail in less than 65 years. The town opted to rebuild the covered bridge.

The bridge is a Town Lattice Truss spanning eighty feet over the Ottauquechee River. Some of the features of the original bridge were changed in the new bridge, most notably, the engineer specified natural ships knees from Maine be used in place of knee braces. Ships knees are usually cut from the base of spruce trees where the trunk creates a natural buttress. Milled carefully, ships knees provide stable bracing that offer greater clearance for vehicles passing through the bridge. Although most of the ships knees in this bridge came from Maine, the project required a few additional knees. Seth and Jan selected appropriate trees from Jan’s property and hewed out the additional ships knees. Each of the knees were scribed in place. Oak sheer keys were added and finally the knees were bolted to the truss and tie beams. Seth and Michael Cotroneo spent may hot July days drilling and sledgehammering two-inch diameter pegs into the lattice truss. With all of the pegs in place, a crane was used to lift the trusses. When the trusses were plumbed, four-inch thick hardwood decking was added along with the board and baton siding. The Bridge was rolled across I beams and lowered down to rest on white oak bearing timbers on the new abutments. The remaining siding work was then finished, and a wooden curb was added to the interior of the bridge before opening it for public use. If you ever find yourself in North Harland, be sure to visit the bridge. It is a rare opportunity to go through two covered bridges back to back.

Monitor Barn, Richmond, VT

Project Overview

I had the great pleasure of working on this frame with Jan Lewandoski. The west monitor barn was constructed in 1903 by Uziel Whitcomb. The barn is home to the Vermont Youth Conservation Corps. Jan was given the task of moving and restoring the frame. Many other contractors and members of VYCC contributed to the finish work of the barn after the frame restoration was completed. The barn measures fifty-four feet wide by seventy-five feet long and almost eighty feet to the cupola. This barn was dismantled and moved back from the road. Due to years of neglect and a soft, local slate roof that hadn’t held up well, this barn was in horrible shape. Only about fifteen percent of the old timbers were able to be used in their original locations, most of which are in the monitor. The original builders of this frame were true masters of square rule joinery, among the best I have seen. The hundred-year-old tenons were cut as smooth as glass. Each tenon in this frame showed a knicker mark at two and one quarter inches from the shoulder. This is evidence of the use of a rabbet plane with a knicker blade. One of the reasons that I love restoration work is for just this sort of opportunity to see evidence of what kind of tools were used and how.

The studs and braces in this frame had only stub tenons that were not pegged. The purlin and top plates extended several feet past the gable ends. The plates were cut to a taper with flashing covering the end grain of the timbers. The framing of this barn is quite different than that of the neighboring monitor barn to the east. Different scarf joints were used, and the purlin system was also done in a different style. The opportunity to work on such a grand structure was humbling for me and a real highlight of my career.

-Seth Kelley

The Big Eddy Bridge, Waitsfield, VT

Project Overview

The Big Eddy bridge, located in Waitsfield, VT, was built in 1833. This Burr arch bridge is 105 feet long by 15 feet wide. In 2006 a truck pulling a camper destroyed three of the bridges tie beams and two of the ships knees.

Meetinghouse in Strafford, VT

Project Overview

The meetinghouse in Strafford, VT has served the townspeople for both secular and religious activities since its construction in 1799. In June of 2004, working as sub-contractors for Jan Lewandoski, we had the opportunity restore the steeple of the meetinghouse. Two of the girts that support the lantern and spire had rolled inward and were in danger of serious failure. We restored the two girts and another on the floor below, that had significant rot, in addition to the bell deck and the junction of the roof with the back of the tower. A wonderful account of the building of the meetinghouse entitled The Town House has been published by Strafford resident Gwenda Smith. Among the accounts offered in her book, we found the names of Leonard Walker, who is known to have built the seven foot weather-vane and cut boards and lath for the meetinghouse, and his brother Freeman Walker who is also believed to have participated in the construction of the meetinghouse. During the restoration we uncovered the carefully scribed initials of the two brothers. Leonard’s initials were found upside down on a rafter beneath the bell deck and Freeman’s were found at the base of one of the octagonal posts. We live for this kind of thing!